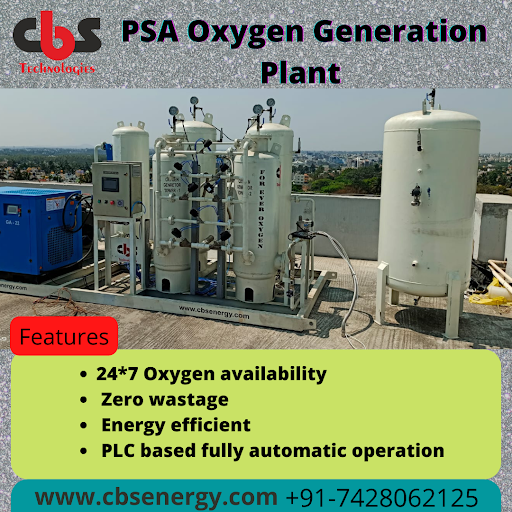

PSA Oxygen Generation Plant

Capacities available from 150LPM to 1500LPM.

CbS's Oxygen Generators and Oxygen Plants use at least two vessels filled with molecular sieve as adsorbers. As compressed air passes through one of the adsorbers, the molecular sieve adsorbs the nitrogen. This allows the remaining oxygen to pass through and exit the adsorber as a product gas. Before the adsorber becomes saturated with nitrogen, the inlet air flow switches to the second adsorber. The first adsorber is now regenerated by desorbing the nitrogen through depressurization and purging it with oxygen. The complete cycle is then repeated. Under normal operating conditions, the molecular sieve is completely regenerative and will last indefinitely.

PSA Medical Oxygen Systems Features

- Oxygen-compatible components

- Produces oxygen from an independent compressed air source

- Highest process efficiency and low operating cost

- Automatic and unattended operation

- Control panel with maintenance-free, solid-state purity monitor, including alarm and shutdown capability

- Easy to install and maintain

Comments

Post a Comment